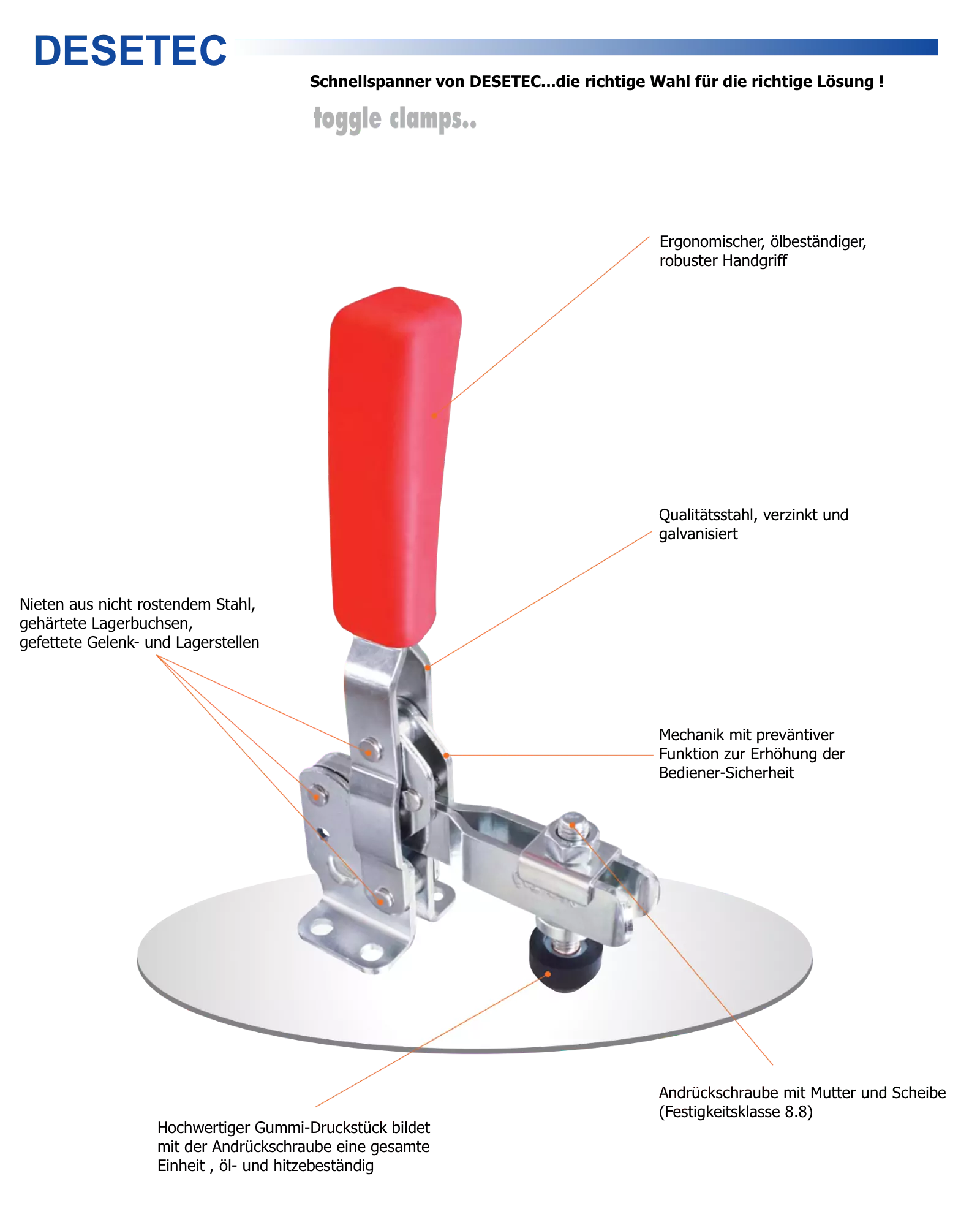

Vertical hold-down toggle clamps with optional locking and/or stainless steel design

Compelling quality for industrial use:Hardened steel galvanized, passivated. Rivets made of stainless steel, case-hardened bearing pins from size 2, lubricated pivot and bearing points. Mechanism with preventive function to increase operator safety. Ergonomic, oil-resistant, sturdy handle in red. Complete with quenched, galvanized pressure screw with nut and washer (FK 8.8). High-quality, elastic rubber pressure pad/protective cap in red or black.

SHORT DELIVERY TIMES | CUSTOMIZED MODIFICATIONS ARE POSSIBLE

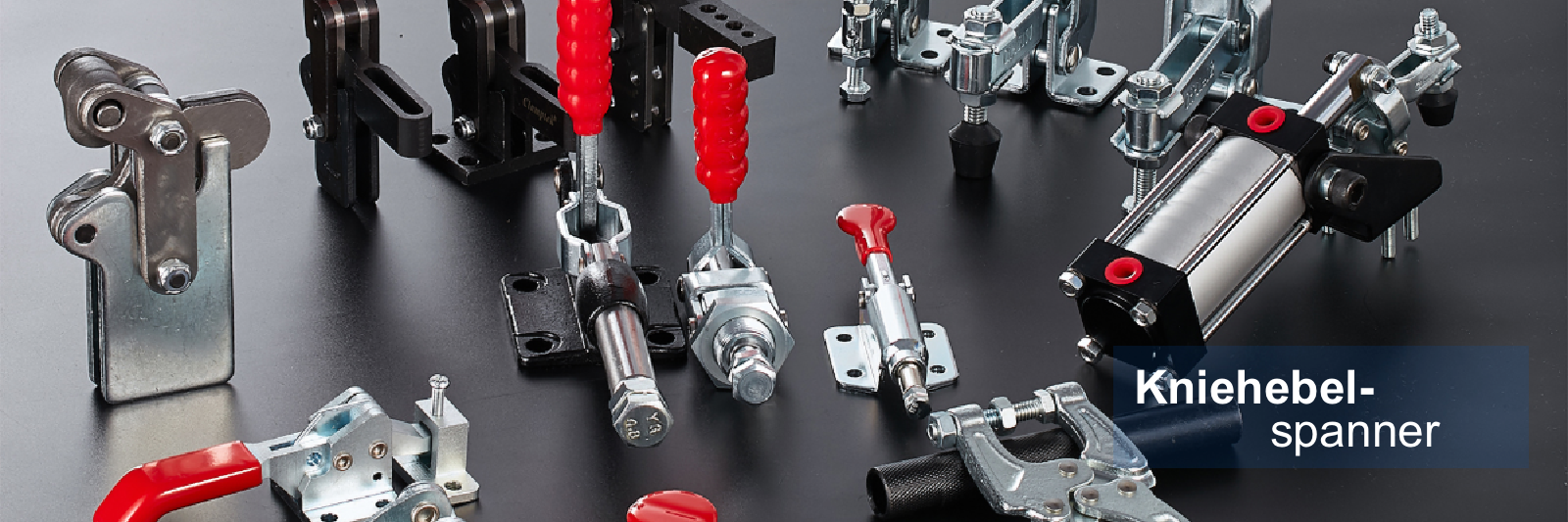

Toggle clamps are operating on the toggle principle. They enable high clamping forces with minimal effort.

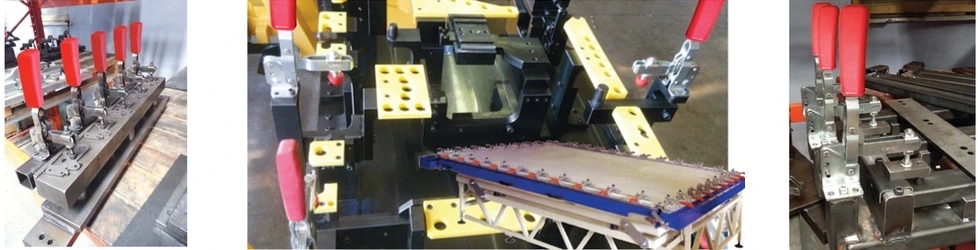

Toggle clamps are used, for example, in the metal industry, tool and fixture construction for clamping during drilling, welding, bending, grinding, testing, and assembly, or in woodworking and plastic processing in glueing, drilling, cutting, and milling fixtures.

Vertical clamps are often also referred to as vertical acting or hold-down clamps or vertical toggle clamps. In the clamping position, the handle is in a vertical position. Versions with an additional safety lock protect against unintentional opening of the clamp.

Our wide product range of vertical clamps includes the following designs:

- Vertical clamps with an open retaining arm (M10, M11, and M12)

- Vertical clamps with a solid retaining arm (M10L, M11L, and M12L)

- Heavy-duty vertical clamps for particularly high clamping and holding forces (M33 and M34)

- Modular clamps - modular vertical clamps in weldable design for particularly high clamping and holding forces (M30 and M32)